|

We're coming back from an insightful 2016 STAR Global Conference in

Prague that focused on discovering better designs, faster. It's

clear that the world of Computer-Aided Engineering (CAE) is

shifting from troubleshooting and verification towards using

modeling and simulation to drive innovation. Below are some

examples of conference presentations that leveraged HEEDS technology

to explore new concepts. As with each edition, we strive to bring

you useful articles and examples of how HEEDS is being used to help

engineers produce better products. Keep reading to learn more about

exciting HEEDS-related happenings.

|

Maximizing Efficiency

of Marine Propellers

Rolla

SP Propellers SA improved the efficiency of a propeller fin cap

system using STAR-CCM+® and Optimate+™(Powered by HEEDS). Boss caps

with fins are intended to recover energy that is lost from the hub

vortex generated by the propeller by redirecting the flux. Proper

design may also reduce damaging cavitation effects. Normally this

type of fin cap system is used on large, low-speed, container ships

with large propeller diameters and low shaft RPM. In this case, a

fast RPM propeller was studied. A fin cap was put after a Rolla

propeller and open water CFD simulations were carried out.

Rolla

SP Propellers SA improved the efficiency of a propeller fin cap

system using STAR-CCM+® and Optimate+™(Powered by HEEDS). Boss caps

with fins are intended to recover energy that is lost from the hub

vortex generated by the propeller by redirecting the flux. Proper

design may also reduce damaging cavitation effects. Normally this

type of fin cap system is used on large, low-speed, container ships

with large propeller diameters and low shaft RPM. In this case, a

fast RPM propeller was studied. A fin cap was put after a Rolla

propeller and open water CFD simulations were carried out.

A design study was

performed to automatically vary 13 parameters representing the

geometry of the fins and cap in an effort to identify designs that

increased efficiency and reduced maximum turbulent kinetic energy

downstream of the propeller. The study resulted in a non-intuitive,

high-performing design. View the presentation from last month's 2016

STAR Global Conference in Prague.

A design study was

performed to automatically vary 13 parameters representing the

geometry of the fins and cap in an effort to identify designs that

increased efficiency and reduced maximum turbulent kinetic energy

downstream of the propeller. The study resulted in a non-intuitive,

high-performing design. View the presentation from last month's 2016

STAR Global Conference in Prague.

|

Improving Heat Transfer in

Rectangular Ducts

Many

applications of industrial interest involve heat transfer across

rectangular ducts of high aspect ratio, for example, forced air

pins--fin cooling of electronic devices or liquid pins--fin cooling

for high power application (hybrid electric vehicles, gas turbine,

blades, etc). The design of these systems aims to provide high heat

transfer rates while maintaining low pressure drop. MBDA Missile

Systems used STAR-CCM+® to first validate against published

experimental data for rectangular ducts with staggered arrays of

short pin fins. Average Nusselt numbers and pressure drop were

shown to correlate well between simulation and experiment. HEEDS

technology was then used to perform direct design search on a

parametric heat exchanger in order to maximize heat transfer while

simultaneously minimizing pressure drop. Vie presentation from last

month's 2016

STAR Global Conference in Prague.

Many

applications of industrial interest involve heat transfer across

rectangular ducts of high aspect ratio, for example, forced air

pins--fin cooling of electronic devices or liquid pins--fin cooling

for high power application (hybrid electric vehicles, gas turbine,

blades, etc). The design of these systems aims to provide high heat

transfer rates while maintaining low pressure drop. MBDA Missile

Systems used STAR-CCM+® to first validate against published

experimental data for rectangular ducts with staggered arrays of

short pin fins. Average Nusselt numbers and pressure drop were

shown to correlate well between simulation and experiment. HEEDS

technology was then used to perform direct design search on a

parametric heat exchanger in order to maximize heat transfer while

simultaneously minimizing pressure drop. Vie presentation from last

month's 2016

STAR Global Conference in Prague.

|

Improving Flow in an Airline

Low-Speed Wind Tunnel

Uniformity

and angularity are characteristics that define the quality of flow

in the test section of a wind tunnel. In RUAG Aviation's large,

low-speed wind tunnel (LWTE), a patchwork of meshes with different

porosities was installed in the third corner of the airline to

improve the flow homogeneity in the test section. A design study

was conducted to identify designs that would maintain flow quality

while minimizing pressure losses. STAR-CCM+® was used to simulate

the complete airline in conjunction with a porous baffle to model

the impact of the meshes. Optimate+™, based on HEEDS technology,

was used to modify the pressure drop across the porous baffle as a

function of position in the wind tunnel cross section to improve

flow uniformity and angularity while reducing pressure drop. The work

was presented at 2016

STAR Global Conference in Prague last month.

Uniformity

and angularity are characteristics that define the quality of flow

in the test section of a wind tunnel. In RUAG Aviation's large,

low-speed wind tunnel (LWTE), a patchwork of meshes with different

porosities was installed in the third corner of the airline to

improve the flow homogeneity in the test section. A design study

was conducted to identify designs that would maintain flow quality

while minimizing pressure losses. STAR-CCM+® was used to simulate

the complete airline in conjunction with a porous baffle to model

the impact of the meshes. Optimate+™, based on HEEDS technology,

was used to modify the pressure drop across the porous baffle as a

function of position in the wind tunnel cross section to improve

flow uniformity and angularity while reducing pressure drop. The work

was presented at 2016

STAR Global Conference in Prague last month.

|

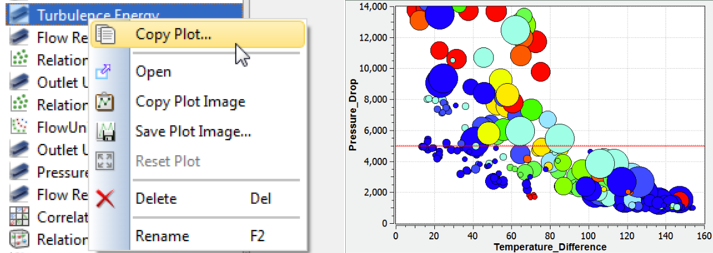

Exploring Design

Performance Relationships

Often, improvements to

the simplest things can have a big impact on your daily tasks.

There are many tasks we perform repeatedly when working with HEEDS,

and streamlining those saves time and reduces effort. HEEDS 2015.11

contains many enhancements focused on simplifying workflows and I

want to highlight a few that help in exploring design performance

relationships.

Often, improvements to

the simplest things can have a big impact on your daily tasks.

There are many tasks we perform repeatedly when working with HEEDS,

and streamlining those saves time and reduces effort. HEEDS 2015.11

contains many enhancements focused on simplifying workflows and I

want to highlight a few that help in exploring design performance

relationships.

In this article, we highlight a few new features that

help you discover better designs, faster. Read

more...

|

2016 International HEEDS User Conference

|

Make plans to attend

the Optimize This!

2016 International HEEDS User Conference on October 12,

2016 in Dearborn, Michigan. Register at http://regonline.com/OptThis2016.

Make plans to attend

the Optimize This!

2016 International HEEDS User Conference on October 12,

2016 in Dearborn, Michigan. Register at http://regonline.com/OptThis2016.

We're still looking for great papers covering a wide range of

design exploration applications using HEEDS products, across all

industries and disciplines. Deadline for abstracts is April 30th. Click

here for more information.

|

|

|

|

2016

Ricardo Software USERCON Europe

4/5-6: Ludwigsburg, Germany

More

info

2016 VI-Grade Users Conference

4/12-13: Wiesbaden, Germany

More

info

ThermoAnalytics User Group Meeting (UGM)

4/19-21: Munich, Germany

More info

2016 CarSim Conference

5/3-4: Novi, MI

More

info

Siemens PLM Connection 2016 - Americas

5/16-19: Orlando, FL

More info

BMES/FDA Frontiers in Medical Devices Conference

5/23-25: College Park, MD

More

info

STAR Japanese Conference 2016

6/9-10: Yokohama, Japan

More info

STAR Chinese Conference 2016

6/13-14: Hangzhou, China

More info

STAR Korean Conference 2016

6/16-17: Seoul, Korea

More info

OptimizeThis! 2016 Conference

10/12/2016: Detroit, MI

More info

|

Powertrain Multidisciplinary Design Exploration

View

Optimization for Powertrain Applications

View

Subsea Design Exploration: Optimizing a Split Lock Ring to Maximize

Load Capacity

View

Tapping into the Unknowns Using HEEDS and Cloud Computing

View

Improving Thrust Reverser Performance Through Design Exploration

View

Better Products Faster through Multidisciplinary Design Exploration

View

|

|

|

Ron

Averill is one of the founders of RCT and a continuing contributor to

our training programs. Ron takes the time to provide some

thought-provoking ideas on expanding the usage of design exploration.

Ron

Averill is one of the founders of RCT and a continuing contributor to

our training programs. Ron takes the time to provide some

thought-provoking ideas on expanding the usage of design exploration.

Error

Designs: Is it OK if Some Simulations Fail during a HEEDS Design

Study?

Error

Designs: Is it OK if Some Simulations Fail during a HEEDS Design

Study?

During a design exploration study, HEEDS makes

many calls to your simulation model to evaluate potential designs.

This means that your model needs to accurately predict design performance

values (objectives and constraints) over a wide range of inputs

(design variables). Most modern simulation models satisfy this

requirement without difficulty. Read more...

|

Please welcome our newest member to

the Red Cedar Technology team.

Hanxiao Ge - Application Engineer

Hanxiao Ge - Application Engineer

Hanxiao Ge, pronounced Hun-shee-yow

Gee, joined RCT as an Applications Engineer in March

2016. He will be very active assisting customers. He recently

obtained a PhD degree in mechanical engineering at the University of

Minnesota Twin Cities, where he worked as a research and teaching

assistant in the Polymer Materials and Mechanics Lab. Prior to that,

he received his bachelor degree from the mechanical engineering

department in Zhejiang University (China). He enjoys traveling, hiking

and making investments.

|

We look forward to our

continued relationship on helping you discover better designs, faster with HEEDS.

Sincerely,

Sincerely,

Val Townsend

|

|

|

|